High Voltage Connector Overview

Lihokelo tsa matla a phahameng, tse tsejoang hape e le lihokelo tsa motlakase o phahameng, ke mofuta oa sehokelo sa likoloi. Ka kakaretso li bua ka lihokelo tse nang le motlakase o sebetsang ka holimo ho 60V mme li ikarabella haholo bakeng sa ho fetisa maqhubu a maholo.

Li-connectors tse nang le matla a phahameng li sebelisoa haholo-holo ho li-circuits tsa likoloi tsa motlakase tse phahameng le tse phahameng hona joale. Ba sebetsa ka lithapo ho tsamaisa matla a pakete ea betri ka lipotoloho tse fapaneng tsa motlakase ho ea ho likarolo tse fapaneng tsa sistimi ea koloi, joalo ka lipakete tsa betri, lilaoli tsa makoloi le li-converter tsa DCDC. lisebelisoa tse nang le matla a phahameng joalo ka li-converter le li-charger.

Hajoale, ho na le litsamaiso tse tharo tsa mantlha tsa lihokelo tsa motlakase o phahameng, e leng LV standard plug-in, USCAR standard plug-in, le Japanese standard plug-in. Har'a li-plug-ins tsena tse tharo, LV hajoale e na le phallo e kholo ka ho fetisisa 'marakeng oa lehae le litekanyetso tse felletseng tsa ts'ebetso.

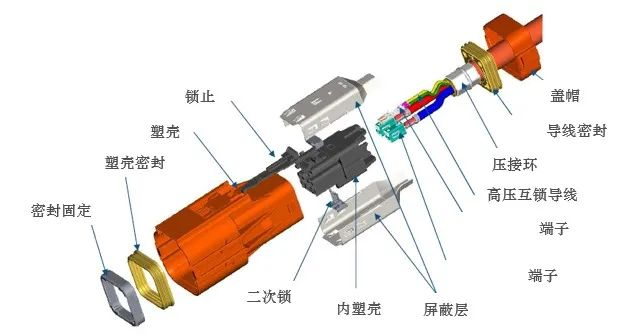

Setšoantšo sa ts'ebetso ea kopano ea sehokelo sa motlakase se phahameng

Sebopeho sa motheo sa sehokelo sa motlakase o phahameng

Lihokelo tsa matla a phahameng haholo li entsoe ka meaho e mene ea mantlha, e leng likhokahano, li-insulators, likhetla tsa polasetiki le lisebelisoa.

(1) Mabitso: likarolo tsa mantlha tse tlatsang likhokelo tsa motlakase, e leng litheminale tsa banna le basali, lehlaka, joalo-joalo;

(2) Insulator: e tšehetsa li-contacts le ho netefatsa ho kenngoa pakeng tsa mabitso, ke hore, khetla ea polasetiki e ka hare;

(3) Khetla ea polasetiki: Khetla ea sehokelo e tiisa ho tsamaisana ha sehokelo le ho sireletsa sehokelo kaofela, ke hore, khetla ea polasetiki e ka ntle;

(4) Lisebelisoa: ho kenyelletsa lisebelisoa tsa meralo le lisebelisoa tsa ho kenya, e leng lithakhisa tse behang sebaka, lithakhisa tsa tataiso, mehele e hokelang, mehele e tiisang, lithapo tse potolohang, meaho ea ho notlela, jj.

Sehokelo sa motlakase o phahameng se phatlohile pono

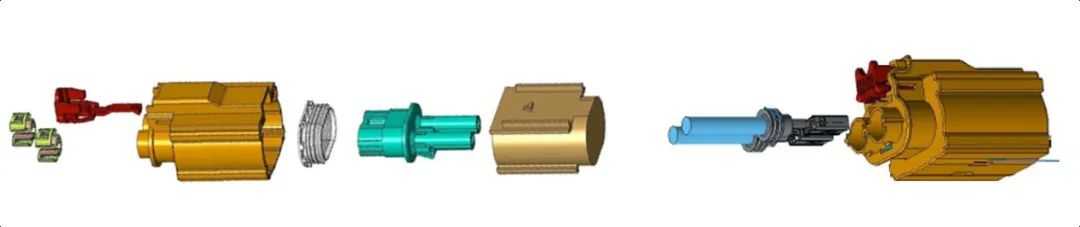

Sehlopha sa li-connectors tse phahameng

Li-connectors tse phahameng li ka khetholloa ka litsela tse ngata. Hore na sehokelo se na le ts'ebetso ea ho sireletsa, palo ea likhokahano, joalo-joalo li ka sebelisoa kaofela ho hlalosa sehlopha sa sehokelo.

1.Hore na ho na le tšireletso kapa che

Lihokelo tse nang le matla a phahameng a matla li arotsoe ka lihokelo tse sa sireletsehang le lihokelo tse sirelelitsoeng ho latela hore na li na le mesebetsi ea ho sireletsa.

Lihokelo tse sa sirelelitsoeng li na le sebopeho se batlang se le bonolo, ha ho ts'ebetso ea tšireletso, le litšenyehelo tse tlase. E sebelisoa libakeng tse sa hlokeng tšireletso, joalo ka lisebelisoa tsa motlakase tse koahetsoeng ke likhese tsa tšepe tse kang li-circuits tsa ho tjhaja, li-betri pack tse ka hare, le li-control tse ka hare.

Mehlala ea lihokelo tse se nang lera le sireletsang le ho se na moralo oa interlock oa matla a phahameng

Lihokelo tse sirelelitsoeng li na le meaho e rarahaneng, litlhoko tsa tšireletso, le litšenyehelo tse batlang li phahame. E loketse libaka tseo ho tsona ho hlokahalang ts'ebetso ea tšireletso, joalo ka moo bokantle ba lisebelisoa tsa motlakase bo hokahaneng le lithapo tse nang le matla a phahameng a matla.

Sehokelo se nang le thebe le moralo oa HVIL Mohlala

2. Palo ea li-plug

Lihokelo tse phahameng tsa motlakase li arotsoe ho latela palo ea likou tsa khokahano (PIN). Hajoale, tse sebelisoang haholo ke sehokelo sa 1P, sehokelo sa 2P le sehokelo sa 3P.

Sehokelo sa 1P se na le sebopeho se batlang se le bonolo ebile se theko e tlase. E kopana le litlhoko tsa ho sireletsa le ho thibela metsi tsa lisebelisoa tse phahameng tsa motlakase, empa mokhoa oa kopano o rarahane hanyenyane 'me ts'ebetso ea ho tsosolosa e fokola. Hangata e sebelisoa ka har'a li-betri pack le li-motors.

Lihokelo tsa 2P le 3P li na le meaho e rarahaneng le litšenyehelo tse batlang li le holimo. E kopana le litlhoko tsa ho sireletsa le ho thibela metsi tsa lisebelisoa tse phahameng tsa motlakase 'me e na le ts'ebetso e ntle ea ho boloka. Ka kakaretso e sebelisoa bakeng sa ho kenya le ho tsoa ho DC, joalo ka lipakete tsa betri tse nang le matla a phahameng, li-terminals, li-terminal tsa charger tsa DC, jj.

Mohlala oa sehokelo sa motlakase o phahameng oa 1P/2P/3P

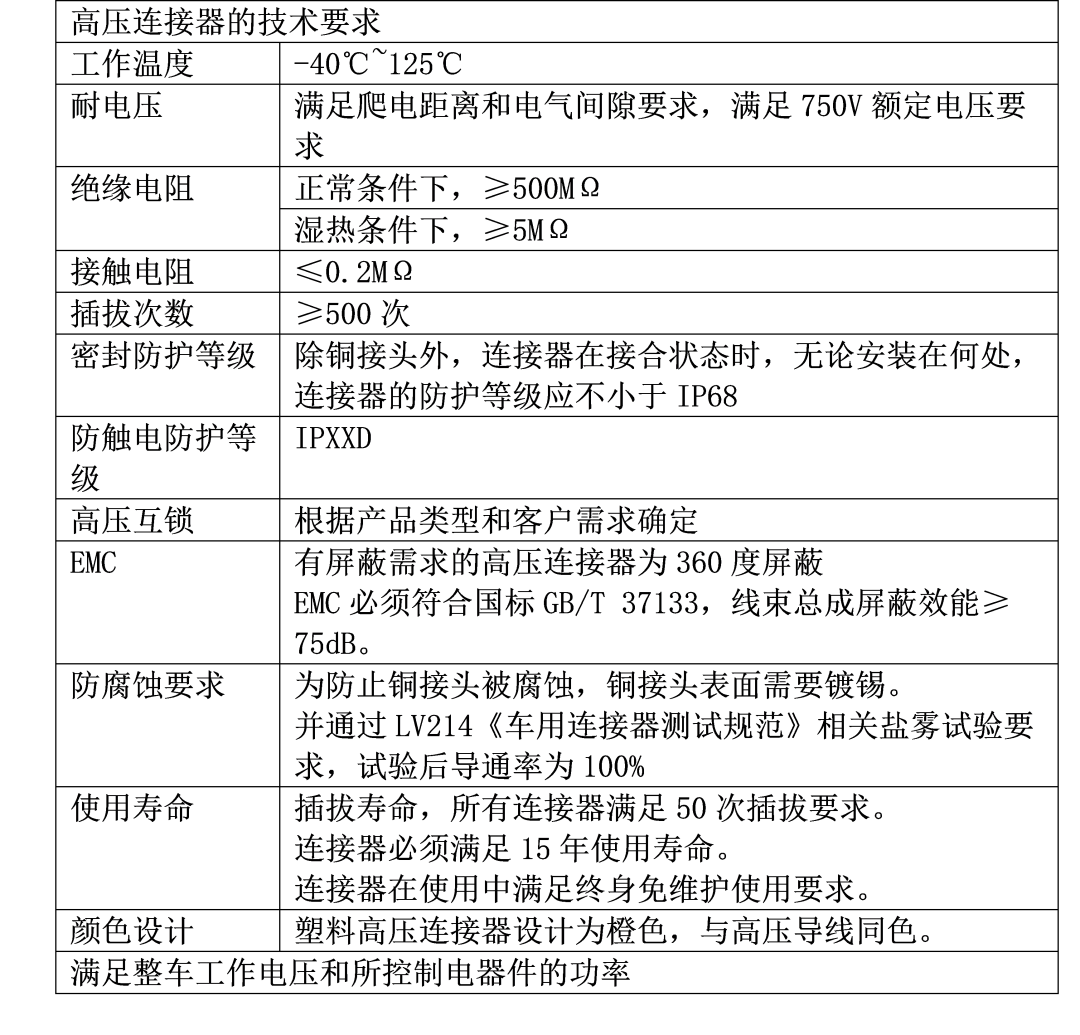

Litlhoko tse akaretsang tsa lihokelo tsa motlakase o phahameng

Lihokelo tsa motlakase o phahameng li lokela ho latela litlhoko tse boletsoeng ke SAE J1742 'me li be le litlhoko tse latelang tsa tekheniki:

Litlhoko tsa tekheniki tse boletsoeng ke SAE J1742

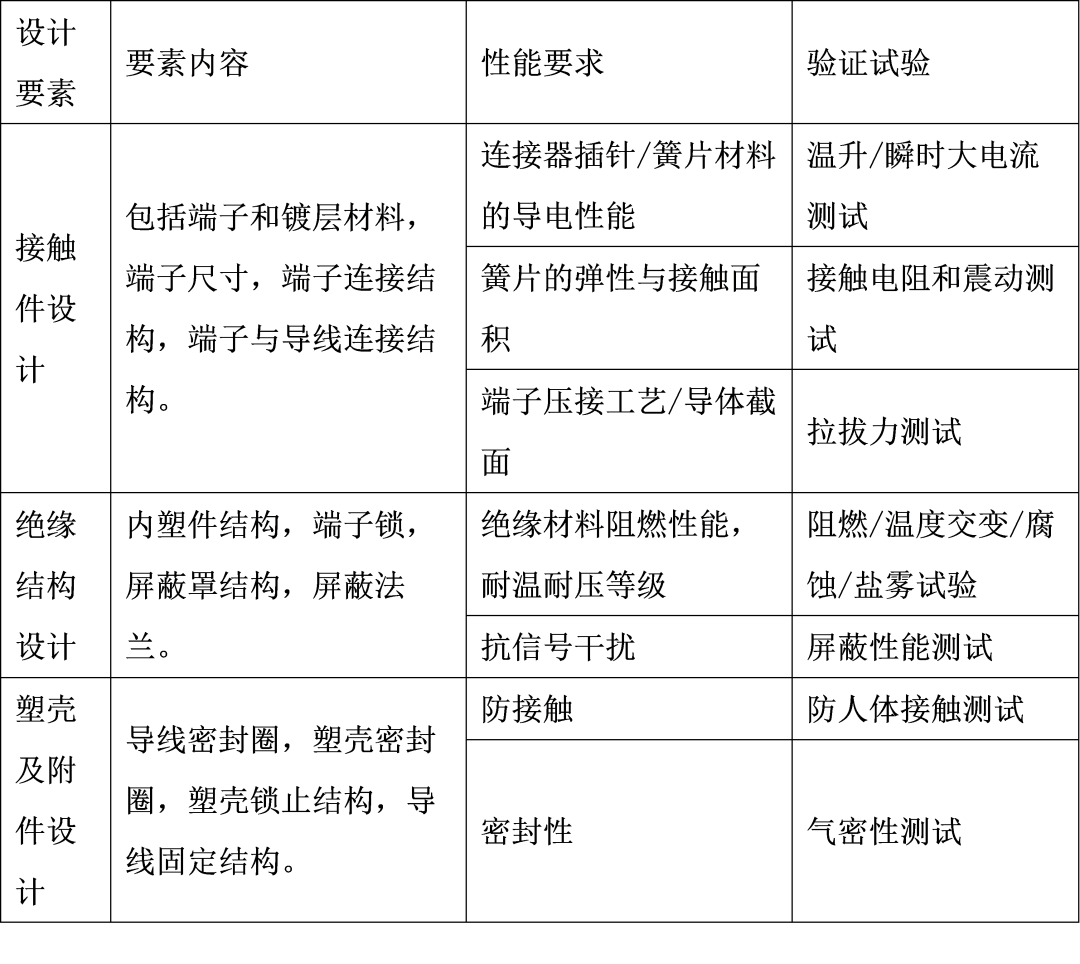

Likarolo tsa moralo oa li-connectors tse phahameng

Litlhoko tsa li-connectors tse nang le matla a phahameng a marang-rang li kenyeletsa empa ha li felle feela ho: matla a phahameng le ts'ebetso e phahameng ea hona joale; tlhoko ea ho khona ho fihlela maemo a phahameng a ts'ireletso tlasa maemo a fapaneng a ts'ebetso (joalo ka mocheso o phahameng, ho thothomela, tšusumetso ea ho thulana, ho thibela lerole le ho thibela metsi, joalo-joalo); Na le instolability; ho ba le ts'ebetso e ntle ea tšireletso ea motlakase; theko e lokela ho ba tlase kamoo ho ka khonehang le ho tšoarella.

Ho ea ka litšoaneleho le litlhoko tse ka holimo tseo li-connectors tse phahameng tsa motlakase li lokelang ho ba le tsona, qalong ea moralo oa li-connectors tse phahameng, lintlha tse latelang tsa moralo li lokela ho nahanoa 'me ho etsoa moralo o lebisitsoeng le ho netefatsa liteko.

Lenane la papiso ea likarolo tsa moralo, ts'ebetso e ts'oanang le liteko tsa netefatso ea lihokelo tse phahameng tsa motlakase

Tlhahlobo ea ho hloleha le mehato e tsamaellanang ea lihokelo tse phahameng tsa motlakase

E le ho ntlafatsa ho tšepahala ha moralo oa sehokelo, mokhoa oa eona oa ho hlōleha o lokela ho hlahlobisisoa pele e le hore mosebetsi oa moralo o thibelang o ka etsoa.

Lihokelo hangata li na le mekhoa e meraro e meholo ea ho hloleha: ho hokahana hantle, ho se tsitse hantle, le ho se lokise.

(1) Bakeng sa ho kopana ho fokolang, matšoao a kang static contact resistance, dynamic contact resistance, matla a karohano ea lesoba le le leng, lintlha tsa ho hokahanya le ho hanyetsa ho sisinyeha ha likarolo li ka sebelisoa ho ahlola;

(2) Bakeng sa ho kenya letsoho ho fokolang, ho hanyetsa ha insulator, tekanyo ea ho senyeha ha nako ea insulator, matšoao a boholo ba insulator, mabitso le likarolo tse ling li ka fumanoa ho ahlola;

(3) Bakeng sa ho tšepahala ha mofuta o tsitsitseng le o thibetsoeng, mamello ea kopano, nako ea mamello, matla a ho boloka pin, matla a ho kenya pin, matla a ho boloka tlas'a maemo a khatello ea tikoloho le matšoao a mang a terminal le sehokelo li ka lekoa ho ahlola.

Kamora ho sekaseka mekhoa e meholo ea ho hloleha le mefuta ea ho se atlehe ha sehokelo, mehato e latelang e ka nkuoa ho ntlafatsa ts'epahalo ea moralo oa sehokelo:

(1) Khetha sehokelo se loketseng.

Khetho ea li-connectors ha ea lokela ho nahana feela ka mofuta le palo ea lipotoloho tse hokahaneng, empa hape e thusa ho hlophisoa ha lisebelisoa. Ka mohlala, lihokelo tse chitja ha li amehe haholo ke boemo ba leholimo le maemo a mochini ho feta lihokelo tse khutlonnetsepa, li na le moaparo o fokolang oa mochini, 'me li hokahane ka ts'epahalo ho lipheletsong tsa terata, kahoo lihokelo tse chitja li lokela ho khethoa ka hohle kamoo ho ka khonehang.

(2) Ha palo e kholo ea mabitso ho sehokelo, e theola ho ts'epahala ha sistimi. Ka hona, haeba sebaka le boima li lumella, leka ho khetha sehokelo se nang le palo e nyane ea mabitso.

(3) Ha u khetha sehokelo, maemo a sebetsang a thepa a lokela ho nkoa.

Lebaka ke hore kakaretso ea hona joale le boholo ba hona joale bo sebetsang ba sehokelo hangata bo khethoa ho latela mocheso o lumelletsoeng ha o sebetsa tlas'a maemo a phahameng a mocheso a tikoloho e potolohileng. E le ho fokotsa mocheso o sebetsang oa sehokelo, maemo a ho senya mocheso a sehokelo a lokela ho nkoa ka botlalo. Ka mohlala, likhokahano tse hole le bohareng ba sehokelo li ka sebelisoa ho hokahanya phepelo ea motlakase, e leng se loketseng ho felloa ke mocheso.

(4) Ho se kene metsi le ho thibela ho bola.

Ha sehokelo se sebetsa tikolohong e nang le likhase tse senyang le lino tse tahang, e le ho thibela ho bola, ho lokela ho lefshoa tlhokomelong ea monyetla oa ho e kenya ka mokhoa o otlolohileng ho tloha lehlakoreng nakong ea ho kenya. Ha maemo a hloka ho kenngoa ka holimo, mokelikeli o lokela ho thibeloa hore o se ke oa phalla ka har'a sehokelo ho latela melapo. Ka kakaretso sebelisa lihokelo tse sa keneleng metsi.

Lintlha tsa bohlokoa moralong oa likhokahano tsa li-high-voltage connector

Theknoloji ea khokahano ea likhokahano e hlahloba haholo sebaka sa ho ikopanya le matla a ho ikopanya, ho kenyeletsoa khokahano lipakeng tsa li-terminals le lithapo, le khokahano ea likhokahano lipakeng tsa li-terminals.

Ho tšepahala ha likhokahano ke ntlha ea bohlokoa ho khethollang ts'epahalo ea sistimi hape ke karolo ea bohlokoa ea kopano eohle ea likhoele tse phahameng tsa motlakase.. Ka lebaka la tikoloho ea ts'ebetso e thata ea li-terminals tse ling, lithapo le likhokahano, khokahano lipakeng tsa li-terminals le lithapo, le khokahano lipakeng tsa li-terminals le li-terminals li atisa ho hloleha ho fapaneng, joalo ka corrosion, botsofali le ho lokoloha ka lebaka la ho thothomela.

Kaha ho se sebetse ha likhoele tsa motlakase ho bakoang ke tšenyo, ho hlepha, ho oa, le ho se sebetse ha mabitso ho feta 50% ea liphoso tsamaisong eohle ea motlakase, tlhokomelo e felletseng e lokela ho lefshoa ho moralo o ts'epahalang oa likhokahano moralong oa ts'epahalo oa sistimi ea motlakase ea matla a phahameng a koloi.

1. Khokahano ea khokahano lipakeng tsa terminal le terata

Khokahano lipakeng tsa li-terminals le lithapo e bolela khokahano lipakeng tsa tse peli ka ts'ebetso ea crimping kapa ts'ebetso ea welding ea ultrasonic. Hajoale, ts'ebetso ea crimping le ultrasonic welding process hangata e sebelisoa ka har'a lithapo tsa terata tse phahameng haholo, e 'ngoe le e' ngoe e na le melemo le likotsi tsa eona.

(1) Ts'ebetso ea crimping

Molao-motheo oa ts'ebetso ea crimping ke ho sebelisa matla a kantle ho petelletsa terata ea conductor sebakeng se senyehileng sa terminal. Bophahamo, bophara, boemo bo fapaneng le matla a ho hula a terminal crimping ke litaba tsa mantlha tsa boleng ba crimping, tse khethollang boleng ba crimping.

Leha ho le joalo, hoa lokela ho hlokomeloa hore microstructure ea leha e le efe e entsoeng hantle e tiileng holim'a metsi e lula e le thata ebile e sa lekane. Ka mor'a hore li-terminals le lithapo li fokotsehe, ha se ho kopana ha sebaka sohle sa ho kopana, empa ho kopana ha lintlha tse ling tse hasaneng holim'a sefahleho sa ho kopana. , sebaka sa sebele sa ho kopana se tlameha ho ba se senyenyane ho feta sebaka sa puisano sa theory, hape ke lebaka leo ka lona khanyetso ea ho kopana ha ts'ebetso ea crimping e phahameng.

Mechanical crimping e ameha haholo ke ts'ebetso ea crimping, joalo ka khatello, bophahamo ba crimping, joalo-joalo Taolo ea tlhahiso e hloka ho etsoa ka mekhoa e kang bolelele ba crimping le tlhahlobo ea profil / tlhahlobo ea metallographic. Ka hona, crimping consistency of the crimping process is average and the tool wear is Tšusumetso e kholo 'me ho tšepahala hoa karolelano.

Ts'ebetso ea crimping ea crimping ea mochini e se e holile ebile e na le mefuta e mengata ea lits'ebetso tse sebetsang. Ke mokhoa oa setso. Hoo e ka bang barekisi bohle ba baholo ba na le lihlahisoa tsa likhoele tse sebelisang mokhoa ona.

Lifaele tsa ho ikopanya le li-terminal le terata ho sebelisa mokhoa oa crimping

(2) Ts'ebetso ea welding ea Ultrasonic

Ultrasonic welding e sebelisa maqhubu a sisinyehang a phahameng haholo ho fetisetsa bokaholimo ba lintho tse peli tse lokelang ho chesetsoa. Tlas'a khatello, bokaholimo ba lintho tse peli lia hohlana ho etsa ho kopana pakeng tsa likarolo tsa molek'hule.

Ultrasonic welding e sebelisa jenereithara ea ultrasonic ho fetolela 50/60 Hz ea hona joale hore e be matla a motlakase a 15, 20, 30 kapa 40 KHz. Matla a matla a motlakase a fetotsoeng a phahameng a fetoloa hape hore e be motsamao oa mochini oa maqhubu a tšoanang ka transducer, ebe motsamao oa mochini o fetisetsoa hloohong ea welding ka sete ea lisebelisoa tsa lenaka tse ka fetolang amplitude. Hlooho ea tjheseletsa e fetisetsa matla a sisinyehang a amohetseng lenonyeletsong la sesebediswa sa mosebetsi hore se tjhesehe. Sebakeng sena, matla a ho sisinyeha a fetoloa matla a mocheso ka ho ferekana, ho qhibilihisa tšepe.

Mabapi le ts'ebetso, ts'ebetso ea welding ea ultrasonic e na le khanyetso e nyane ea ho kopana le mocheso o tlase oa overcurrent ka nako e telele; mabapi le tšireletseho, e ka tšeptjoa ebile ha ho bonolo ho e lokolla le ho oela tlas'a ho sisinyeha ha nako e telele; e ka sebelisoa bakeng sa tjheseletsa pakeng tsa thepa e fapaneng; e angoa ke oxidation ea holim'a metsi kapa ho roala Ka mor'a moo; boleng ba welding bo ka ahloloa ka ho lekola mefuta e nepahetseng ea ts'ebetso ea crimping.

Le hoja litšenyehelo tsa thepa ea ultrasonic welding process li batla li le holimo, 'me likarolo tsa tšepe tse lokelang ho ts'oaroa li ke ke tsa e-ba tse teteaneng haholo (ka kakaretso ≤5mm), ultrasonic welding ke mokhoa oa mechine 'me ha ho na phallo ea hona joale nakong ea ts'ebetso eohle ea welding, kahoo ha ho na Litaba tsa ho khanna mocheso le resistivity ke mekhoa ea nakong e tlang ea ho roala mohala o phahameng oa motlakase.

Li-terminals le li-conductor tse nang le welding ea ultrasonic le likarolo tsa tsona tsa ho kopana

Ho sa tsotelehe ts'ebetso ea crimping kapa ultrasonic welding process, kamora hore terminal e hokahane le terata, matla a eona a ho hula a tlameha ho fihlela litlhoko tse tloaelehileng. Ka mor'a hore terata e hokahane le sehokelo, matla a ho hula ha aa lokela ho ba ka tlase ho matla a fokolang a ho hula.

Nako ea poso: Dec-06-2023