Ha li-conductors tsa aluminium li ntse li sebelisoa ka ho eketsehileng lithapong tsa likhoele tsa likoloi, sengoloa sena se sekaseka le ho hlophisa theknoloji ea khokahano ea likhoele tsa terata ea aluminium, 'me se sekaseka le ho bapisa ts'ebetso ea mekhoa e fapaneng ea khokahano ho nolofatsa khetho ea morao-rao ea mekhoa ea khokahanyo ea likhoele tsa aluminium.

01 Kakaretso

Ka khothaletso ea ts'ebeliso ea li-conductors tsa aluminium lithapong tsa likhoele tsa koloi, ts'ebeliso ea li-conductors tsa aluminium sebakeng sa li-conductor tsa koporo tsa setso e ntse e eketseha butle-butle. Leha ho le joalo, ts'ebetsong ea lithapo tsa aluminium tse nkelang lithapo tsa koporo sebaka, kutu ea electrochemical, creep e phahameng ea mocheso, le conductor oxidation ke mathata a tlamehang ho tobana le ho rarolloa nakong ea ts'ebetso. Ka nako e ts'oanang, ts'ebeliso ea lithapo tsa aluminium tse nkelang lithapo tsa koporo sebaka li tlameha ho fihlela litlhoko tsa mehala ea pele ea koporo. Lisebelisoa tsa motlakase le tsa mochini ho qoba ho senyeha ha ts'ebetso.

Bakeng sa ho rarolla mathata a kang electrochemical corrosion, mocheso o phahameng oa mocheso, le oxidation ea conductor nakong ea ts'ebetso ea lithapo tsa aluminium, hajoale ho na le mekhoa e mene ea khokahano indastering, e leng: friction welding le pressure welding, friction welding, ultrasonic welding, le plasma welding.

Se se latelang ke tshekatsheko le papiso ya tiragatso ya melawana ya kgolagano le dipopego tsa mefuta e mene e ya dikgokaganyo.

02 friction welding le khatello ea welding

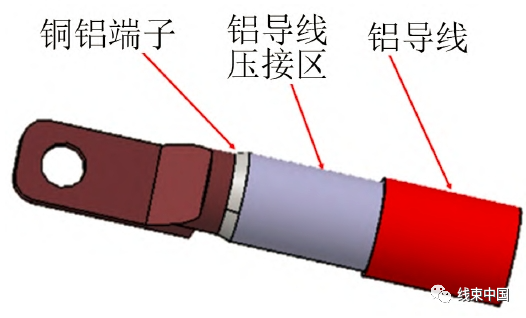

Ho tjheseletsa ha friction le ho kopanya khatello, qala ka ho sebedisa dithupa tsa koporo le aluminium bakeng sa ho tjheseletsa ho hohlang, ebe o hatakela melamu ya koporo ho etsa dikgokelo tsa motlakase. Lithupa tsa aluminium li entsoe ka mochini le ho bōptjoa ho etsa lipheletso tsa crimp tsa aluminium, 'me liteishene tsa koporo le aluminium lia hlahisoa. Ebe terata ea aluminium e kenngoa pheletsong ea aluminium ea crimping ea terminal ea koporo-aluminium 'me e phunyeletsoa ka har'a lisebelisoa tsa khale tsa terata ho phethela khokahano lipakeng tsa conductor ea aluminium le theminale ea koporo-aluminium, joalo ka ha ho bonts'itsoe ho Setšoantšo sa 1.

Ha ho bapisoa le mefuta e meng ea likhokahano, tšubuhlellano ea likhohlano le welding ea khatello e theha sebaka sa phetoho sa koporo-aluminium alloy ka ho khoasolla lithupa tsa koporo le melamu ea aluminium. Sebaka sa ho tjheseletsa se na le sebopeho se ts'oanang le se teteaneng, ka katleho se qoba bothata ba ho phalla ha mocheso o bakoang ke li-coefficients tse fapaneng tsa katoloso ea mocheso oa koporo le aluminium. , Ho phaella moo, ho thehoa ha sebaka sa phetoho ea alloy ho boetse ho qoba ho senyeha ha electrochemical ho bakoang ke mesebetsi e fapaneng ea tšepe pakeng tsa koporo le aluminium. Ho tiisoa ka mor'a moo ka li-tubes tse fokotsang mocheso ho sebelisoa ho arola sefafatsi sa letsoai le mouoane oa metsi, oo hape o thibelang ho hlaha ha kutu ea electrochemical. Ka hydraulic crimping ea terata ea aluminium le qetello ea aluminium ea crimp ea koporo-aluminium terminal, sebopeho sa monofilament sa mokhanni oa aluminium le lera la oxide leboteng le ka hare la aluminium crimp end li senyeha 'me li qhibililoe,' me joale serame se phethoa pakeng tsa lithapo tse le 'ngoe le pakeng tsa lerako la aluminium conductor le lerako la conductor ea aluminium. Motsoako oa welding o ntlafatsa ts'ebetso ea motlakase oa khokahanyo mme o fana ka ts'ebetso e tšepahalang ka ho fetisisa ea mochini.

03 tšubuhlellano ea likhohlano

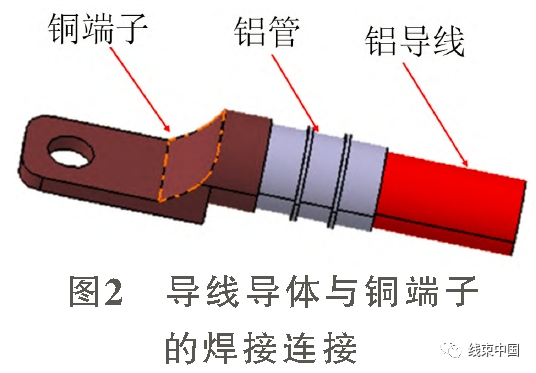

Friction welding e sebelisa tšupu ea aluminium ho holisa le ho bopa conductor ea aluminium. Kamora ho khaola sefahleho sa ho qetela, welding ea likhohlano e etsoa ka terminal ea koporo. Khokahano ea tjheseletsa lipakeng tsa khondara ea terata le theminale ea koporo e phetheloa ka ho khoasolla ha likhohlano, joalo ka ha ho bontšitsoe setšoantšong sa 2.

friction welding e kopanya mehala ea aluminium. Ntlha ea pele, tube ea aluminium e kenngoa ho conductor ea terata ea aluminium ka crimping. Sebopeho sa monofilament sa mokhanni se entsoe ka polasetiki ka crimping ho etsa karolo e thata ea selikalikoe. Ebe karolo ea welding cross-section e batalatsoa ka ho reteleha ho phethela ts'ebetso. Ho lokisoa ha libaka tsa welding. Qetello e 'ngoe ea terminal ea koporo ke sebopeho sa khokahano ea motlakase, 'me pheletso e' ngoe ke sebaka sa khokahanyo ea li-welding tsa terminal ea koporo. The tjheseletsa kgokelo holim'a terminal koporo le holim'a tjheseletsa holim'a terata aluminium li tjheseletsa le ho hokela ka khohlano tjheseletsa, 'me joale tjheseletsa flash e khaola le bōpehile ho phetha tshebetso ya kgokelo ya khohlano tjheseletsa terata aluminium.

Ha ho bapisoa le mefuta e meng ea likhokahano, tšubuhlellano ea likhohlano e theha khokahano ea phetoho lipakeng tsa koporo le aluminium ka ho khoahlapisa pakeng tsa liteishene tsa koporo le lithapo tsa aluminium, ka katleho ho fokotsa ho bola ha electrochemical ea koporo le aluminium. The copper-aluminium friction welding transition zone e tiisitsoe ka sekhomaretsi se honyetseng li-tubing hamorao. Sebaka sa tjheseletsa se ke ke sa pepeseha moeeng le mongobo, ho fokotsa ho senya ho eketsehileng. Ho phaella moo, sebaka sa ho tjheseletsa ke moo mokhanni oa terata ea aluminium o kopantsoeng ka ho toba le setsi sa koporo ka ho tjheseletsa, e leng se eketsang ka katleho matla a ho hula a kopantsoeng le ho etsa hore mokhoa oa ho sebetsa o be bonolo.

Leha ho le joalo, bofokoli bo boetse bo teng mabapi le kamano pakeng tsa lithapo tsa aluminium le li-terminals tsa koporo-aluminium ho Setšoantšo sa 1. Tšebeliso ea tšubuhlellano ea likhohlano ho bahlahisi ba lisebelisoa tsa terata e hloka lisebelisoa tse khethehileng tsa ho roala likhohlano, tse nang le mekhoa e mengata e fokolang le e eketsang matsete a thepa e tsitsitseng ea baetsi ba lisebelisoa tsa mohala. Taba ea bobeli, ka tšubuhlellano ea likhohlano Nakong ea ts'ebetso, sebopeho sa terata sa monofilament se ferekanngoa ka kotloloho le setsi sa koporo, se bakang likhohlano sebakeng sa khokahanyo ea likhohlano. Ho ba teng ha lerōle le litšila tse ling ho tla ama boleng ba ho qetela ba tjheseletsa, ho baka ho se tsitse ha thepa ea mechine le ea motlakase ea khokahanyo ea welding.

04 Ultrasonic welding

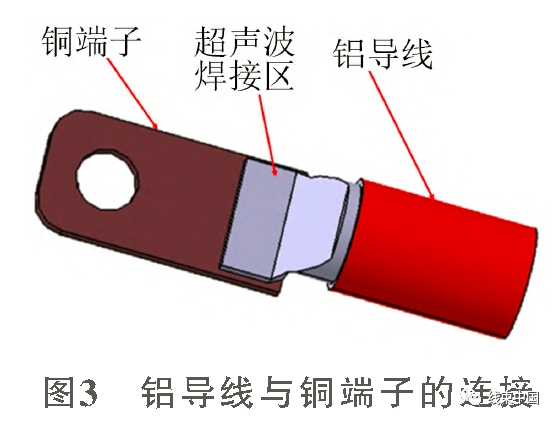

Ultrasonic welding ea mehala ea aluminium e sebelisa lisebelisoa tsa ultrasonic welding ho hokahanya lithapo tsa aluminium le liteishene tsa koporo. Ka "high-frequency oscillation of the welding head of the ultrasonic welding equipment, aluminium wire monofilaments le terata ea aluminium le li-terminals tsa koporo li kopantsoe hammoho ho tlatsa mohala oa aluminium le Khokahano ea li-terminals tsa koporo e bontšoa ho Setšoantšo sa 3.

Ultrasonic welding connection ke ha lithapo tsa aluminium le liteishene tsa koporo li thothomela ka maqhubu a phahameng a maqhubu a ultrasonic. Ho thothomela le khohlano lipakeng tsa koporo le aluminium li tlatsa khokahano lipakeng tsa koporo le aluminium. Hobane bobeli ba koporo le aluminium li na le sebopeho sa kristale ea tšepe ea li-cubic tse bohareng ba sefahleho, sebakeng se phahameng sa maqhubu a oscillation Tlas'a boemo bona, phetoho ea athomo mohahong oa kristale ea tšepe e phethiloe ho etsa lera la phetoho ea alloy, ka katleho ho qoba ho etsahala ha kutu ea electrochemical. Ka nako e ts'oanang, nakong ea ts'ebetso ea ultrasonic welding, lesela la oxide holim'a aluminium conductor monofilament le tlosoa, 'me joale ho phethoa ha tšubuhlellano pakeng tsa monofilaments, e leng ho ntlafatsang thepa ea motlakase le ea mechine ea ho hokahanya.

Ha ho bapisoa le liforomo tse ling tsa khokahano, lisebelisoa tsa welding tsa ultrasonic ke lisebelisoa tse sebelisoang hangata bakeng sa baetsi ba likhoele tsa mohala. Ha e hloke matsete a macha a tsitsitseng. Ka nako e ts'oanang, li-terminals li sebelisa li-terminals tsa koporo, 'me litšenyehelo tsa ho qetela li tlaase, kahoo li na le molemo o motle ka ho fetisisa oa litšenyehelo. Leha ho le joalo, ho boetse ho na le mathata. Ha ho bapisoa le mefuta e meng ea khokahanyo, welding ea ultrasonic e na le thepa e fokolang ea mochini le ho hanyetsa ho sisinyeha ho fokolang. Ka hona, ts'ebeliso ea likhokahano tsa welding ea ultrasonic ha e khothalletsoe libakeng tse nang le maqhubu a phahameng a sisinyehang.

05 Ho cheseletsa ka plasma

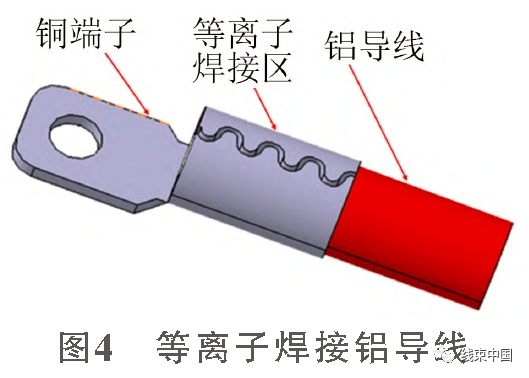

Plasma welding e sebelisa li-terminals tsa koporo le lithapo tsa aluminium bakeng sa khokahanyo ea crimp, ebe ka ho eketsa solder, plasma arc e sebelisetsoa ho khantša le ho futhumatsa sebaka se lokelang ho chesetsoa, ho qhibilihisa solder, ho tlatsa sebaka sa ho tjheseletsa, le ho tlatsa khokahanyo ea terata ea aluminium, joalokaha ho bontšitsoe setšoantšong sa 4.

Ho cheselletsa plasma ea li-conductors tsa aluminium ho qala ka ho sebelisa plasma welding ea litheminale tsa koporo, 'me ho holisa le ho tiisa li-conductors tsa aluminium ho phetheloa ka ho khirisoa. Li-terminals tsa plasma welding li theha sebopeho se bōpehileng joaloka moqomo ka mor'a ho crimping, ebe sebaka sa welding sa terminal se tlatsitsoe ka solder e nang le zinki, 'me qetello ea crimped ke Add solder e nang le zinki. Tlas'a mahlaseli a plasma arc, solder e nang le zinki e futhumala ebile e qhibiliha, ebe e kena ka lekhalo la terata sebakeng sa crimping ka khato ea capillary ho phethela mokhoa oa ho kopanya li-terminals tsa koporo le lithapo tsa aluminium.

Lithapo tsa aluminium tse cheselletsang plasma li tlatsa khokahano e potlakileng lipakeng tsa mehala ea aluminium le liteishene tsa koporo ka crimping, e fana ka thepa e tšepahalang ea mochini. Ka nako e ts'oanang, nakong ea ts'ebetso ea crimping, ka tekanyo ea compression ea 70% ho ea ho 80%, ho timetsoa le ho tlosoa ha lesela la oxide la mokhanni ho phethoa, ka katleho ho Ntlafatsa ts'ebetso ea motlakase, ho fokotsa ho hanyetsa ho kopana ha lintlha tsa khokahanyo, le ho thibela ho futhumala ha lintlha tsa khokahanyo. Ebe u eketsa solder e nang le zinc ho ea qetellong ea sebaka sa crimping, 'me u sebelise sefate sa plasma ho khantša le ho futhumatsa sebaka sa welding. Solder e nang le zinki e futhumatsoa ebile e qhibilihisoa, 'me solder e tlatsa lekhalo sebakeng sa crimping ka ketso ea capillary, ho finyella metsi a fafatsang letsoai sebakeng sa crimping. Ho aroloa ha mouoane ho qoba ho hlaha ha kutu ea electrochemical. Ka nako e ts'oanang, hobane solder e arotsoe ebile e koetsoe, ho thehoa sebaka sa phetoho, se thibelang ka katleho ho hlaha ha mocheso o chesang le ho fokotsa kotsi ea ho eketseha ha khanyetso tlas'a litšisinyeho tse chesang le tse batang. Ka plasma welding ea sebaka sa khokahanyo, ts'ebetso ea motlakase ea sebaka sa ho hokahanya e ntlafatsoa ka katleho, 'me thepa ea mechine ea sebaka sa ho hokahanya le eona e ntlafatsoa le ho feta.

Ha ho bapisoa le mefuta e meng ea khokahanyo, tjheseletsa ea plasma e arola li-terminals tsa koporo le li-conductors tsa aluminium ka lera la phetoho le ho matlafatsa tjheseletsa, ka katleho ho fokotsa ho bola ha electrochemical ea koporo le aluminium. 'Me lera le matlafalitsoeng la welding le koahela sefahleho sa ho qetela sa mokhanni oa aluminium e le hore liteishene tsa koporo le mokokotlo oa conductor li se ke tsa kopana le moea le mongobo, ho fokotsa kutu le ho feta. Ho phaella moo, lera la tjheseletsa la phetoho le lera le matlafalitsoeng la welding ka thata-thata ho lokisa li-terminals tsa koporo le manonyeletso a terata ea aluminium, ka katleho ho eketsa matla a ho hula a manonyeletso le ho etsa hore mokhoa oa ho sebetsa o be bonolo. Leha ho le joalo, ho boetse ho na le mathata. Ho sebelisoa ha plasma welding ho bahlahisi ba likhoele tsa mehala ho hloka lisebelisoa tse arohaneng tsa plasma tsa ho cheseletsa, tse nang le mekhoa e mebe e mengata le ho eketsa matsete a thepa e tsitsitseng ea bahlahisi ba likhoele tsa mehala. Taba ea bobeli, ts'ebetsong ea welding ea plasma, solder e phethoa ka ketso ea capillary. Ts'ebetso ea ho tlatsa lekhalo sebakeng sa crimping ha e laolehe, e fella ka boleng bo sa tsitsang ba ho tjheseletsa sebakeng sa khokahano sa plasma welding, e leng se bakang ho kheloha ho hoholo ts'ebetsong ea motlakase le mochini.

Nako ea poso: Feb-19-2024